How Does a Cleanroom Split System DX HVAC System Work?

Cleanroom Split System DX HVAC Systems

A cleanroom split system DX HVAC (Direct Expansion Heating, Ventilation, and Air Conditioning) is a type of cooling system commonly used in smaller cleanroom environments where central chilled-water systems may not be feasible. The system utilizes refrigerant to provide cooling and humidity control within the cleanroom and is designed to provide precise environmental control for cleanrooms, ensuring temperature, humidity, and air quality are maintained within specific parameters.

Here is a brief explanation of how it works:

- The split system consists of an indoor air handling unit (AHU) and an outdoor condensing unit. These two components are connected via refrigerant lines.

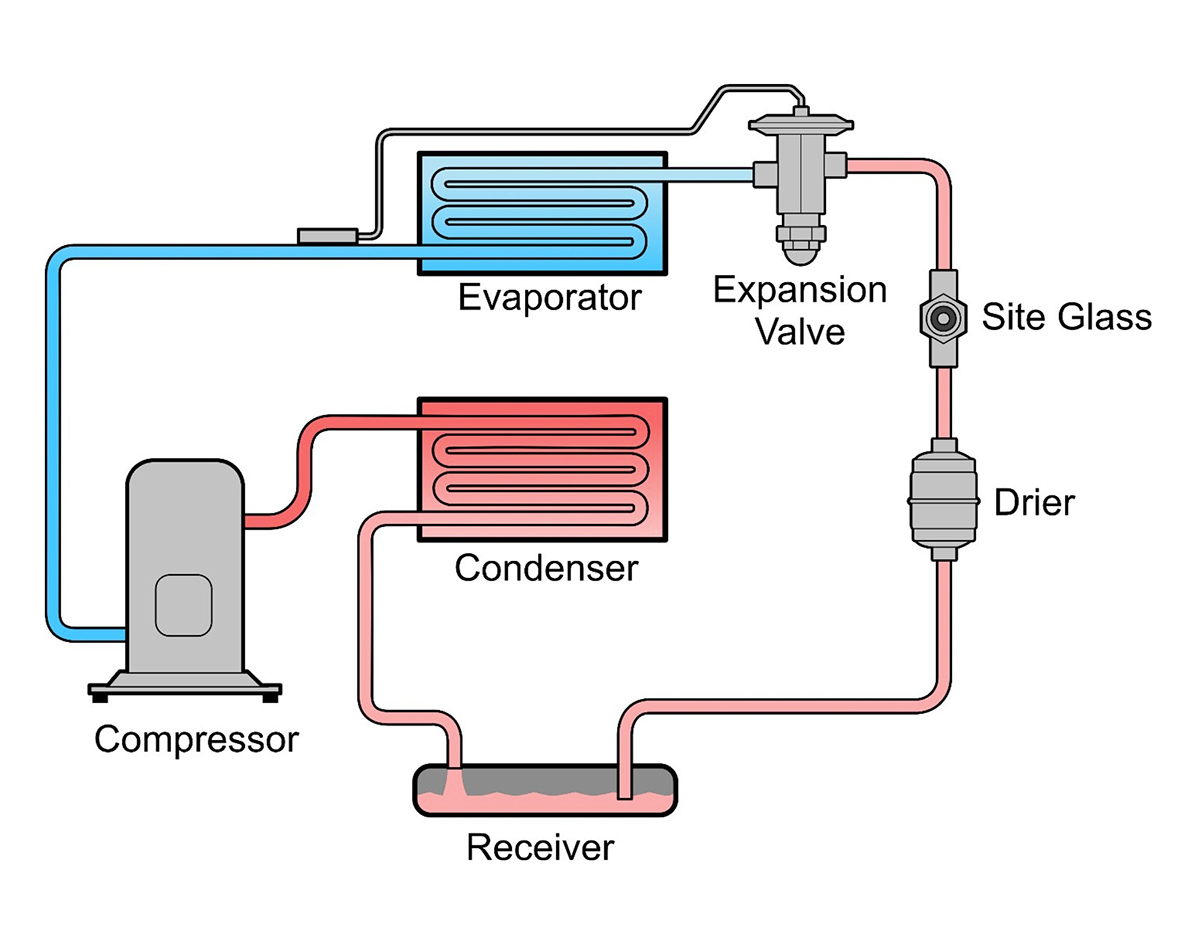

- The indoor AHU, or evaporator, is typically mounted within the cleanroom space. It has a coil filled with refrigerant, which absorbs heat from the air passing over it. This process cools the air, which is then circulated throughout the cleanroom. The refrigerant, now in a gaseous state, is sent back to the outdoor condensing unit.

- In the outdoor AHU, or condenser, the compressor compresses the refrigerant gas, raising its temperature and pressure. The gas then flows through the condenser coil, where the heat is released to the outside air, and the refrigerant condenses back into a liquid state.

- The liquid refrigerant is sent back to the indoor AHU, and the process repeats.

- The cleanroom’s HVAC system also includes High-Efficiency Particulate Air (HEPA)/Ultra-Low Penetration Air (ULPA) filters to remove airborne particles and ensure that the air is clean to meet the specific room classification standards. Additionally, it can control the humidity level as required.

- The system is carefully controlled and monitored to maintain the desired temperature, humidity, and air quality, ensuring consistency and proper conditions within the cleanroom.

Cleanroom split system DX HVAC systems offers a cost-effective and flexible solution for achieving temperature and humidity control necessary for various sensitive applications such as scientific research, electronics manufacturing, and pharmaceutical production. However, for larger cleanrooms, centralized HVAC systems are more commonly employed for enhanced efficiency and performance.

Contact our Cleanroom experts to discuss your cleanroom needs.