news & insights

Precision Environments Donates School Supplies to Crayons to Computers

This fall, employees from Precision Environments delivered a monetary donation and over 1,000 items of school supplies including markers, mechanical pencils, notebooks, paper, highlighters, crayons, colored pencils, and index cards to Crayons to Computers in Cincinnati’s Bond Hill neighborhood.

2024 Big Guy’s Helpers Golf Scramble

For years, Doug Cooper, Precision Environments’ founder and retired President, and a group of friends had been informally “adopting” local families and providing presents at Christmas time. However, they realized the need was great throughout the year, not just at...

Precision Environments’ Donation to CAIN Rainbow Choice Food Pantry

On June 3, 2024, employees from Precision Environments delivered a monetary donation and 2 SUV loads of breakfast bars and cereal, microwavable meals and soups, and juices to the Churches Active in Northside’s (CAIN) Rainbow Choice Food Pantry on Hamilton Avenue in Northside. The food will be distributed to the unhoused and to children who don’t have access to regular meals due to school being out for the summer. Precision Environments’ organizer, Beth Clark, commented, “We do our food drive at this time of year since most people do it around Thanksgiving and Christmas. These items are needed all year round.”

Designing Cleanrooms to Mitigate Microbial Contamination

In industries like pharmaceuticals, biotechnology, and medical devices, cleanrooms are essential for maintaining the integrity of processes and products. For cleanrooms requiring the control of microorganisms, often involving sporicidal agents and other chemicals, careful design is crucial to manage contamination risks effectively.

CLEANROOM FILTRATION & HVAC SYSTEMS

Cleanrooms are critical environments where the slightest contamination can compromise product quality, research integrity, or even human health. Whether it’s pharmaceuticals, electronics, biotechnology, or aerospace, maintaining precise cleanliness standards is of the highest importance. Key aspects of cleanroom design are air filters and Heating, Ventilation, and Air Conditioning (HVAC) systems, which are engineered to remove particles and pollutants

A Guide to Cleanroom Wall Systems

Designing and building an efficient and hygienic cleanroom environment requires careful consideration of the wall system you use. Cleanroom wall panels provide the framework for your controlled environment, ensuring it meets strict standards of cleanliness and functionality. There are a range of wall panel systems tailored to different cleanroom requirements. Let’s explore the options available and the advantages they offer.

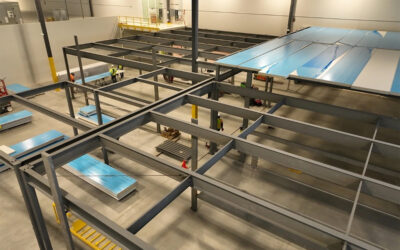

Structural Support In Cleanroom Systems

Cleanrooms are critical environments used in various industries such as pharmaceuticals, biotechnology, electronics manufacturing, and aerospace. Maintaining the highest levels of cleanliness and controlling environmental factors like particulate matter, temperature, humidity, and pressure is essential for the success of operations within cleanrooms. However, achieving these stringent requirements relies on the structural support systems that uphold the integrity of the cleanroom environment. In this blog post, we will look at some ways cleanroom systems are structurally supported.

Different Types of Cleanrooms in Various Industries

Cleanrooms serve as critical environments across diverse industries, ensuring product quality, safety, and compliance with regulatory standards. Let us explore several types of cleanrooms and give a quick look at their applications:

A Reference Point for Cleanroom Classifications

When it comes to creating a cleanroom environment, one of the fundamental questions that arises is, which ISO 14644-1 standard should be adopted?. These standards, ranging from ISO 1 to ISO 9, dictate the maximum allowable particles per cubic meter, with particle sizes ranging from 0.1 µm to ≥5 µm. However, understanding these classifications requires more than just numbers and ranges; it demands a real-world perspective on particle sizes and contamination sources.

An Introduction to the Question: What is a Cleanroom?

The cleanroom industry is diverse and intriguing, with each cleanroom tailored to its specific purpose. Unlike a one-size-fits-all approach, cleanrooms are uniquely designed to…