Cleanroom Plenum Systems vs. Direct-Ducted HVAC Systems

What is the Difference Between a Cleanroom Plenum System vs. a Direct-Ducted HVAC System

Cleanroom Plenum and Direct-Ducted Heating, Ventilation, and Air Conditioning (HVAC) systems are two different types of air handling/ventilation systems used in cleanrooms. The components of each system are outlined below:

Plenum System:

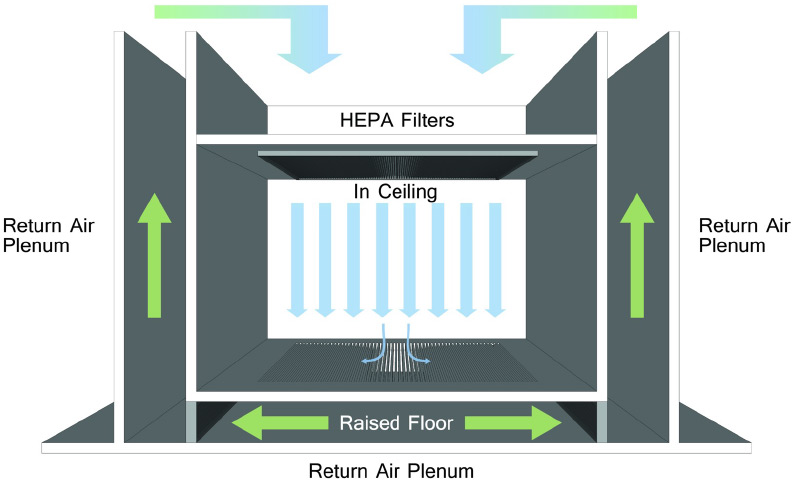

The Plenum System in a cleanroom refers to the space above the ceiling where the supply air is introduced and distributed throughout the cleanroom. It typically consists of a network of ducts, filters, and diffusers. Here’s how the system generally works:

- Air Handling Unit (AHU): The plenum system starts with an Air Handling Unit, which is responsible for conditioning the air by cooling, heating, and filtering it before supplying it to the cleanroom.

- Filters: The AHU incorporates high-efficiency particulate air (HEPA) or ultra-low particulate air (ULPA) filters to remove contaminants from the incoming air. These filters are designed to capture particles as small as 0.3 µ (HEPA) or even smaller (ULPA).

- Ductwork: After passing through the filters, the filtered air is distributed through a network of ducts. The ductwork is typically made of materials that minimize particle shedding, such as stainless steel.

- Plenum: The ductwork leads to the plenum, which is a large space located above the cleanroom ceiling. The plenum acts as a buffer zone for the air supply and allows for even distribution of the conditioned air throughout the cleanroom.

- Diffusers: Within the plenum, there are diffusers or perforated panels installed in the cleanroom ceiling. These diffusers release the filtered air into the cleanroom space and are designed to create uniform airflow patterns and minimize turbulence, ensuring consistent air distribution.

The plenum system plays a crucial role in maintaining the cleanliness and air quality within a cleanroom. It enables the delivery of filtered and conditioned air while preventing the introduction of contaminants from the ventilation system itself. By maintaining positive pressure relative to adjacent areas, the plenum system helps prevent the infiltration of unfiltered air from outside the cleanroom.

Cleanroom Air Plenum System

Direct-Ducted HVAC System:

A Direct-Ducted HVAC System refers to a type of system where air is directly supplied and returned through ductwork, typically without the use of a plenum or ceiling void. The air handling unit (AHU) or HVAC equipment is typically located either within the conditioned space or in a mechanical room adjacent to the space. Here’s how the system generally works:

- Air Supply: The AHU draws in outside air or recirculates indoor air, depending on the design and requirements. It conditions the air by cooling or heating it as needed.

- Filtration: The conditioned air passes through filters in the AHU to remove dust, particles, and other contaminants. The filters help improve indoor air quality by capturing airborne pollutants.

- Ductwork: Once conditioned and filtered, the air is distributed through a network of ducts. The ductwork carries the air from the AHU to the different rooms or zones in the building.

- Air Registers: In each room or zone, air registers or diffusers are installed in the walls, floors, or ceilings. These registers supply the conditioned air into the cleanroom.

- Return Air: Return air registers are also installed in each room or zone to capture the air from the cleanroom and return it back to the AHU for reconditioning. The return air is typically ducted back to the AHU through separate ductwork.

Cleanroom Air Plenum System

Direct-ducted HVAC systems offer several advantages:

Cleanroom Air Plenum System

- Flexibility: The system allows for individual control of temperature and airflow in each room or zone, providing personalized comfort.

- Energy Efficiency: By having separate ducts for supply and return air, the system can be designed to minimize air leakage and improve overall energy efficiency.

- Space Efficiency: Direct-ducted systems eliminate the need for a plenum or ceiling void, which can be beneficial in buildings with limited ceiling space.

- Easy Maintenance: The accessibility of the ductwork and equipment simplifies maintenance and servicing tasks.

Both Cleanroom Plenum and Direct-Ducted HVAC systems are designed to maintain cleanliness and control in a cleanroom environment, but each may be suitable for different applications depending on their specific needs and requirements. It’s essential to consult with a design/build cleanroom specialist such as Precision Environments to determine the best air handling solution for your needs for your project.