Different Types of Cleanrooms in Various Industries

DIFFERENT TYPES OF CLEANROOMS IN VARIOUS INDUSTRIES

Cleanrooms serve as critical environments across diverse industries, ensuring product quality, safety, and compliance with regulatory standards. Let us explore several types of cleanrooms and give a quick look at their applications:

Semiconductor Cleanrooms

Semiconductor manufacturing demands the highest level of contamination control to ensure the reliability and performance of electronic components. Precision Environments’ semiconductor cleanrooms (Photo 1) are engineered to eliminate contaminants such as particulates, gases, and static, crucial for semiconductor fabrication processes. These cleanrooms feature advanced filtration systems and precise environmental control, enabling semiconductor manufacturers to achieve optimal production yields.

Biotech Cleanrooms

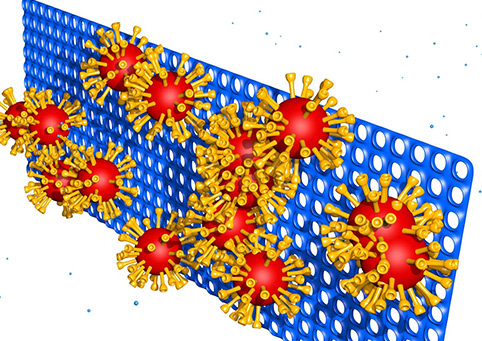

Biotech cleanrooms are at the forefront of scientific research and development, utilizing controlled environments that conform to a high standard. These cleanrooms are engineered to minimize bio-contamination, making them suitable for activities such as cell culture, gene therapy, and pharmaceutical production. Precision Environment’s biotech cleanrooms (Photo 2) adhere to stringent cGMP standards, offering solutions that meet the highest quality and compliance requirements in the biotech industry.

Medical Device Manufacturing and Packaging Cleanrooms

Cleanrooms in medical device manufacturing and packaging are essential for ensuring product quality and safety. These cleanrooms are designed to meet stringent regulatory standards, including Federal Standard 209E and ISO 14644 classifications. Precision Environments’ medical device cleanrooms (Photo 3) provide controlled environments that minimize the risk of contamination, protecting both the products and end-users.

Manufacturing Cleanrooms

Manufacturing cleanrooms play a vital role in producing critical components across industries such as automotive, aerospace, and electronics. These cleanrooms typically adhere to ISO Class 7 or 8 standards, requiring precise control over temperature, humidity, and air quality. Precision Environments’ modular wall systems offer customizable solutions for manufacturing cleanrooms (Photo 4), facilitating the production of high-quality products while meeting regulatory requirements.

Pharmaceutical Compounding Cleanrooms

Cleanrooms compliant with USP<797>, USP<800>, and Sections 503A and 503B of the FD&C Act are crucial for pharmaceutical compounding. These cleanrooms ensure the sterility and integrity of compounded medications, protecting patient safety. Precision Environments’ solutions provide the necessary infrastructure for compounding pharmacies (Photo 5) to maintain strict control over environmental conditions, preventing cross-contamination and ensuring compliance with regulatory standards set by the State Boards of Pharmacy and the FDA.

Cleanrooms play a pivotal role in maintaining product quality, safety, and regulatory compliance across various industries. Precision Environments’ expertise in cleanroom design and construction ensures that businesses can meet their specific requirements while adhering to industry standards. Whether it is biotech research, pharmaceutical compounding, manufacturing, medical device production, or semiconductor fabrication, Precision Environments provides tailored solutions to support critical processes and ensure success. Learn more about our cleanroom services.

Precision Environments Suite of Cleanroom Photos

Jeff Meek

Regional Sales Manager

Recent Posts

Precision Environments, Inc.

Corporate Headquarters

4440 Lake Forest Drive Suite 120

Cincinnati, OH 45242

Phone: 513-847-1510