Five Cleanroom Technologies to Consider on Your Next Project

Emerging Cleanroom Technology

The evolution of technology is a complex process influenced by a wide range of factors including scientific advancements, societal needs, economic factors, and human creativity. As a result, cleanroom technologies are keeping pace with this continuous evolution, especially in the biomedical, pharmaceutical, and electronics industries. Here are five emerging cleanroom technologies that have gained attention recently:

- Advanced Air Filtration Systems: These systems utilize cutting-edge techniques, such as High-Efficiency Particulate Air (HEPA) or Ultra Low Penetration Air (ULPA) filters, to improve air circulation, enhance the removal of airborne contaminants, and maintain a sterile environment. Filter manufacturers often develop new technologies in air filter media materials and filter pack depths, and perform research & development based on pressure drop filter performance data. There is also an increase in the number of smart-fan filter units (FFUs) being designed to provide greater control and automation of the cleanroom.

- Energy-Efficient Cleanrooms: With a growing focus on environmental sustainability and reduction in energy consumption, energy-efficient cleanrooms are using emerging technologies like light-emitting diode (LED) lighting, energy-recovery ventilators, and high-performance heating, ventilation, and air conditioning (HVAC) systems to minimize their environmental footprint. Contact us to assist with designing and building a smart cleanroom system that incorporates an energy-efficient design approach.

- Modular Cleanrooms: Modular and flexible designs cater to the changing needs of various industries by allowing easy expansion, reconfiguration, and relocation of the cleanroom. This reduces construction time and enables businesses to adapt quickly to new requirements. Precision Environments regularly re-configures cleanrooms for our clients as their manufacturing processes change.

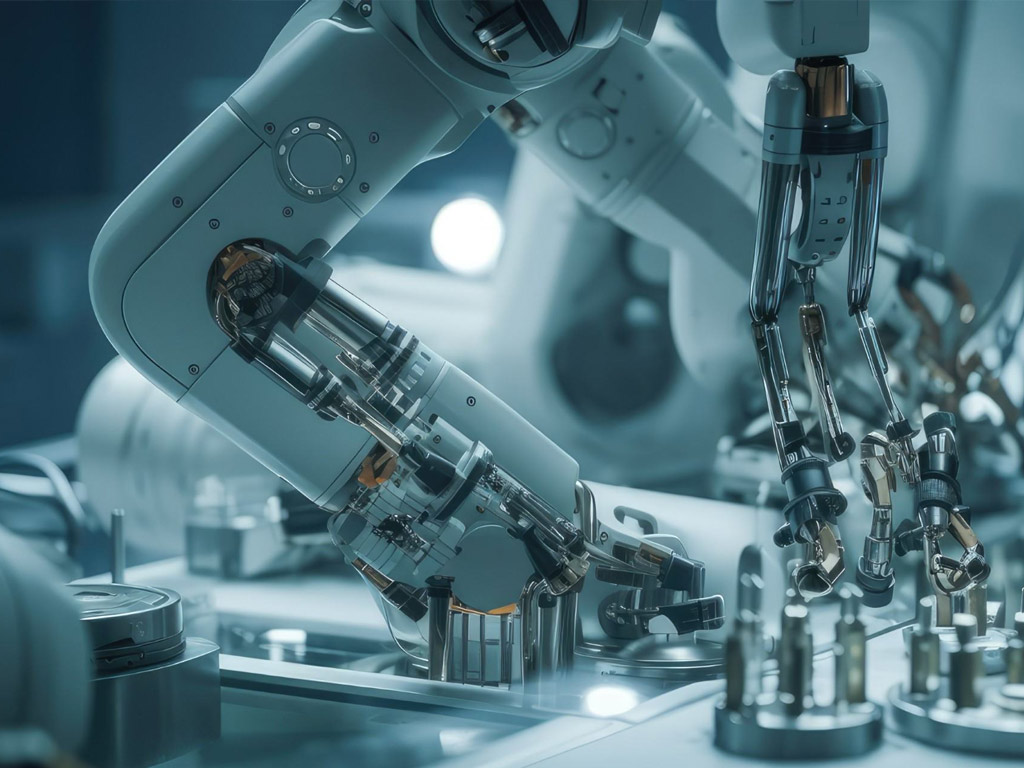

- Automation and Robotics: Integration of automation and robotics in cleanrooms can reduce human intervention and contamination risks, leading to improved accuracy, repeatability, and efficiency in processes. We have seen an increase in the number of automated doors, pass-throughs, and conveyor systems being designed into new cleanroom projects and can help integrate them into your cleanroom plan.

- Smart Cleanroom Monitoring Systems: Internet of Things (IoT) and advanced sensors are being used to provide real-time monitoring of cleanroom environmental conditions, such as temperature, humidity, pressurization, and particulate levels. These smart monitoring systems provide better control over cleanroom conditions, resulting in process optimization and maintenance of the highest level of cleanliness.

Contact our Cleanroom experts to discuss incorporating cutting-edge technology into your next cleanroom project.