What are Aerospace Cleanrooms?

Aerospace Cleanrooms

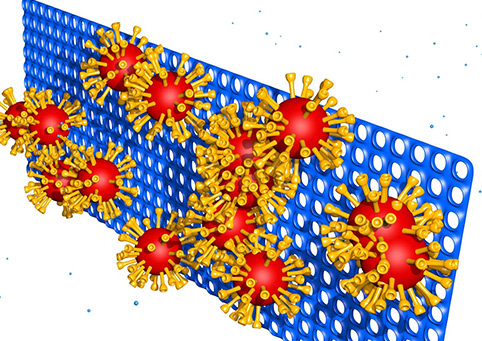

Aerospace cleanrooms play a critical role in maintaining the quality, reliability, and performance of aerospace systems by providing controlled and sterile environments for manufacturing, assembly, and testing processes in the production of satellites, spacecraft, aircraft components, and sensitive electronics. They are particularly crucial for applications involving precision instruments, optical systems, electronic circuitry, and propulsion systems, where even the smallest particles or contaminants such as dust, airborne microbes, aerosol particles, moisture, electromagnetic interference, and chemical vapors can cause significant damage or operational failures.

Several common applications of aerospace cleanrooms include:

- Satellite and Spacecraft Production: Critical components of satellites and spacecraft require a cleanroom environment to avoid contamination that could lead to mission failure or a shortened lifespan.

- Optics and Sensor Systems: Cleanrooms are used for the production and assembly of precision optical instruments, such as telescopes and cameras, which need to remain free of dust and contaminants.

- Avionics and Electronics Manufacturing: Contamination-sensitive electronic components such as circuit boards are often assembled and tested in cleanrooms to ensure quality and reliability.

- Propulsion Systems: The intricate components of engines and propulsion systems require a controlled environment to prevent damage from foreign objects or particles during assembly and testing.

To maintain cleanliness, aerospace cleanrooms are built with specialized features:

- Air Filtration Systems: Aerospace cleanrooms have highly efficient air filtration systems to continuously circulate and filter the air. High-efficiency particulate air (HEPA) filters are commonly used to remove particles as small as 0.3 micrometers.

- Controlled Air Pressure: Aerospace cleanrooms are pressurized to prevent external air from entering and to ensure that any potential contaminants are pushed out when doors are opened. Positive pressure is maintained to prevent airborne particles from infiltrating the cleanroom.

- Temperature and Humidity Control: Aerospace cleanrooms typically maintain specific temperature and humidity levels to prevent moisture-related issues and to optimize the performance of delicate components.

- Cleanroom Garments: Personnel working within the aerospace cleanrooms environment must wear specialized cleanroom garments including cleanroom suits, gloves, masks, and shoe covers to minimize the introduction of particles from their bodies or clothing.

- Cleanroom Protocols: Strict protocols and procedures are implemented in aerospace cleanrooms to minimize contamination risks. These may include gowning procedures, material and tool handling protocols, equipment sterilization, and regular cleaning schedules.

Contact our Cleanroom experts to discuss your next aerospace cleanroom project.