CLEANROOM FILTRATION & HVAC SYSTEMS

Cleanrooms are critical environments where the slightest contamination can compromise product quality, research integrity, or even human health. Whether it’s pharmaceuticals, electronics, biotechnology, or aerospace, maintaining precise cleanliness standards is of the highest importance. Key aspects of cleanroom design are air filters and Heating, Ventilation, and Air Conditioning (HVAC) systems, which are engineered to remove particles and pollutants:

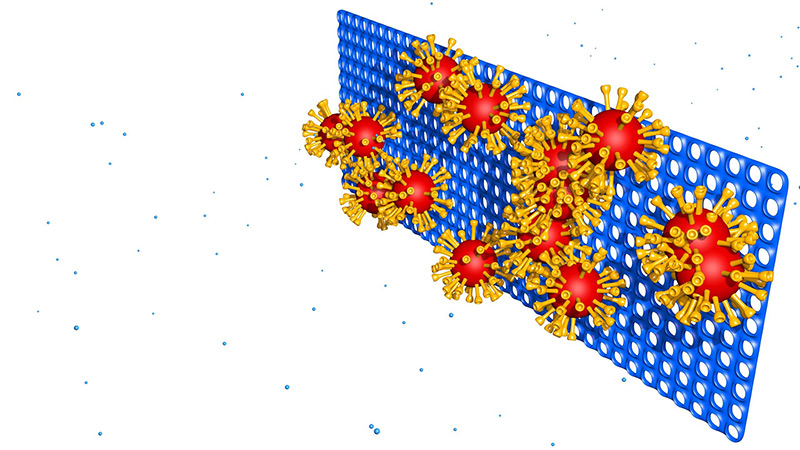

HEPA & ULPA Filters — High-Efficiency Particulate Air (HEPA) filters are the workhorses of cleanrooms. They capture particles as small as 0.3 microns with 99.97% efficiency. These filters consist of a dense mat of randomly arranged fibers that trap particles through diffusion, interception, and inertial impaction. For size reference, the length of a typical bacterium is between 1 and 10 microns.

Ultra-Low Particulate Air (ULPA) filters offer even higher filtration efficiency, capturing particles as small as 0.12 microns with similar efficiency to HEPA filters. ULPA filters are utilized in industries requiring ultra-clean environments, such as semiconductor manufacturing and nanotechnology.

Filter Media — The choice of filter media is crucial for achieving desired filtration performance. Synthetic materials like fiberglass, polypropylene, and polytetrafluoroethylene (PTFE) are commonly used for their high filtration efficiency and durability. Additionally, antimicrobial coatings can inhibit microbial growth on filter surfaces, maintaining cleanliness over extended periods.

Air Handling Systems & FFUs — Air handling systems play a crucial role in the cleanroom operation, controlling airflow, pressure differentials, temperature, and humidity. Positive pressure systems prevent outside contamination by maintaining higher pressure inside the cleanroom. This forces air to flow outward restricting the ability for particles to flow into clean areas. Conversely, negative pressure systems are employed in environments where harmful particles/material should not exit the area. Negative pressure cleanrooms offer containment of material in areas where hazardous materials are handled such as chemotherapy drugs.

Fan Filter Units (FFUs) are self-contained modules comprised of a fan, filter, and motor. They provide localized filtration and airflow control, ensuring uniform distribution of clean air within the cleanroom. FFUs are versatile and can be easily integrated into existing cleanroom designs or modular cleanroom enclosures.

Cleanroom Design Considerations

Designing an effective cleanroom requires careful consideration of various factors including airflow patterns, personnel traffic, equipment layout, and environmental controls. Heat loads from equipment and personnel are also important factors to understand as they will affect the HVAC system’s required cooling capacity. Low humidity rooms may also need to incorporate a desiccant unit to keep humidity levels lower than what is possible using a typical HVAC set up.

Continuous Monitoring and Maintenance

Maintaining cleanroom integrity is an ongoing process that requires regular monitoring and maintenance. Particle counters, air velocity meters, and differential pressure gauges are used to assess cleanroom performance and identify potential issues. Routine filter replacement and cleaning are essential to prevent filter degradation and maintain filtration efficiency.

In summary, air filters and HVAC systems are the cornerstone of cleanroom environments, safeguarding product quality, research integrity, and human health. From HEPA and ULPA filters to sophisticated air handling systems and FFUs, each component plays a vital role in maintaining cleanliness standards. By understanding the principles behind cleanroom filtration and adopting best practices in design and maintenance, industries can ensure the integrity and reliability of their processes in the most demanding environments.

Jeff Meek

Regional Sales Manager

Recent Posts

Precision Environments, Inc.

Corporate Headquarters

4440 Lake Forest Drive Suite 120

Cincinnati, OH 45242

Phone: 513-847-1510