by Jeff Meek | Apr 6, 2024 | Cleanroom Blog, Cleanroom Knowledge Base, Jeff Meek

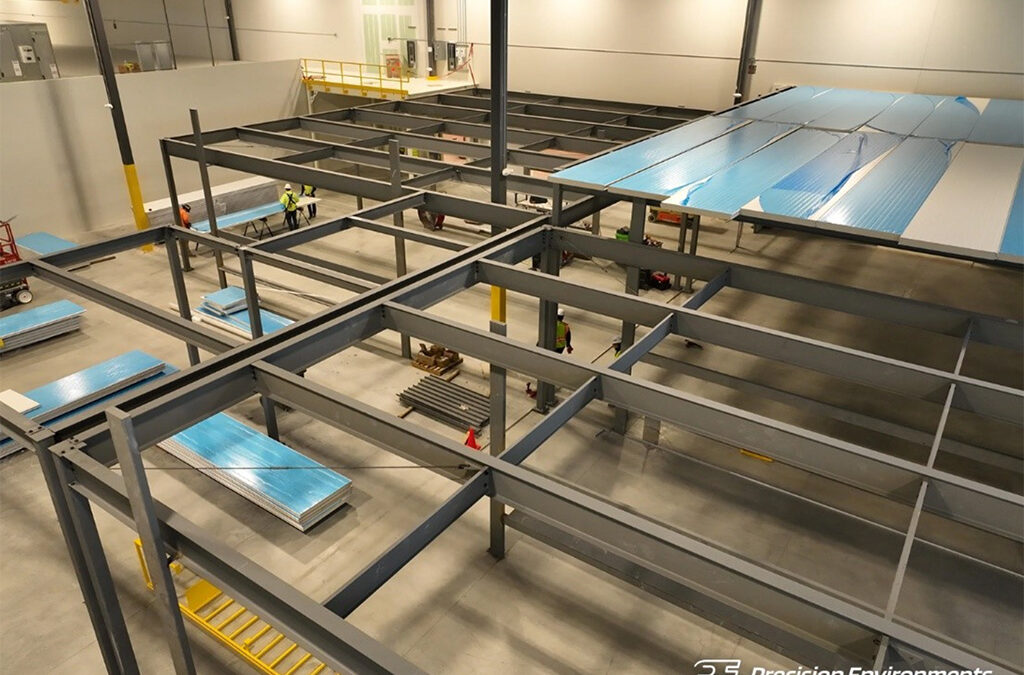

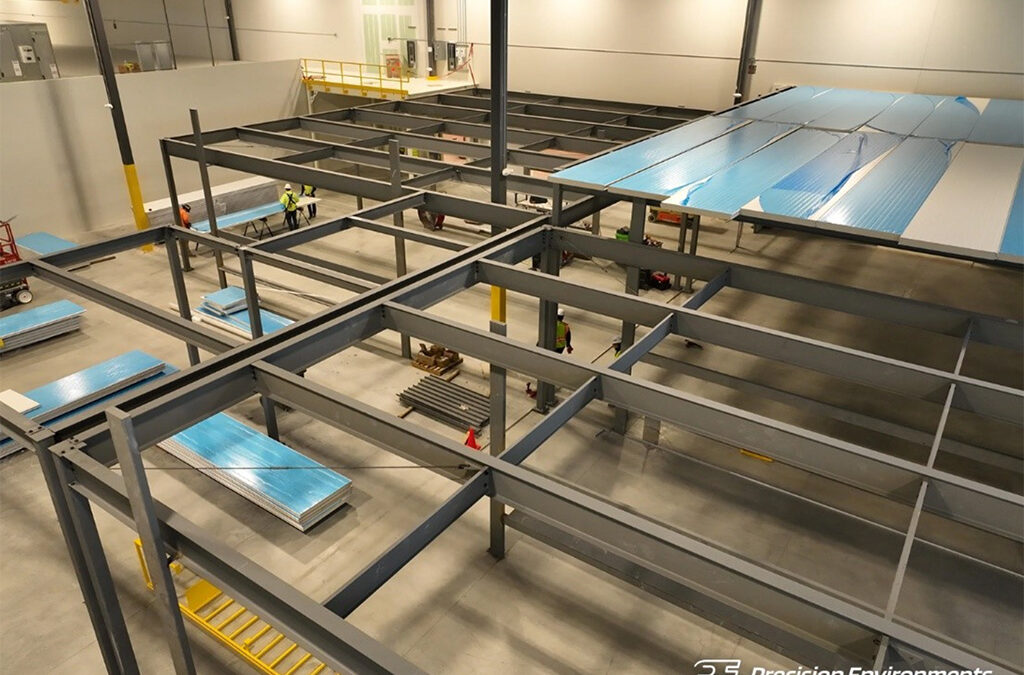

Cleanrooms are critical environments used in various industries such as pharmaceuticals, biotechnology, electronics manufacturing, and aerospace. Maintaining the highest levels of cleanliness and controlling environmental factors like particulate matter, temperature, humidity, and pressure is essential for the success of operations within cleanrooms. However, achieving these stringent requirements relies on the structural support systems that uphold the integrity of the cleanroom environment. In this blog post, we will look at some ways cleanroom systems are structurally supported.

by Jeff Meek | Mar 26, 2024 | Cleanroom Blog, Cleanroom Knowledge Base, Jeff Meek

Cleanrooms serve as critical environments across diverse industries, ensuring product quality, safety, and compliance with regulatory standards. Let us explore several types of cleanrooms and give a quick look at their applications:

by Jeff Meek | Mar 12, 2024 | Cleanroom Blog, Cleanroom Knowledge Base, Cleanroom Standards, Jeff Meek

When it comes to creating a cleanroom environment, one of the fundamental questions that arises is, which ISO 14644-1 standard should be adopted?. These standards, ranging from ISO 1 to ISO 9, dictate the maximum allowable particles per cubic meter, with particle sizes ranging from 0.1 µm to ≥5 µm. However, understanding these classifications requires more than just numbers and ranges; it demands a real-world perspective on particle sizes and contamination sources.

by Jeff Meek | Feb 23, 2024 | Cleanroom Blog, Jeff Meek

The cleanroom industry is diverse and intriguing, with each cleanroom tailored to its specific purpose. Unlike a one-size-fits-all approach, cleanrooms are uniquely designed to…

by Precision Environments | Aug 30, 2023 | Cleanroom Blog, Cleanroom Knowledge Base

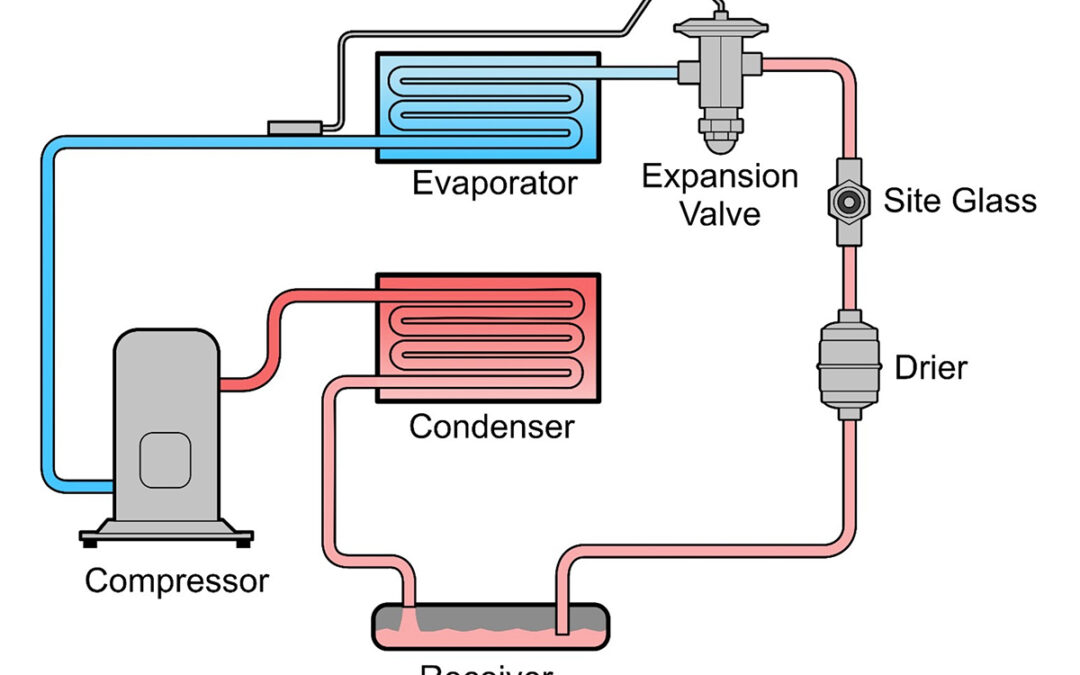

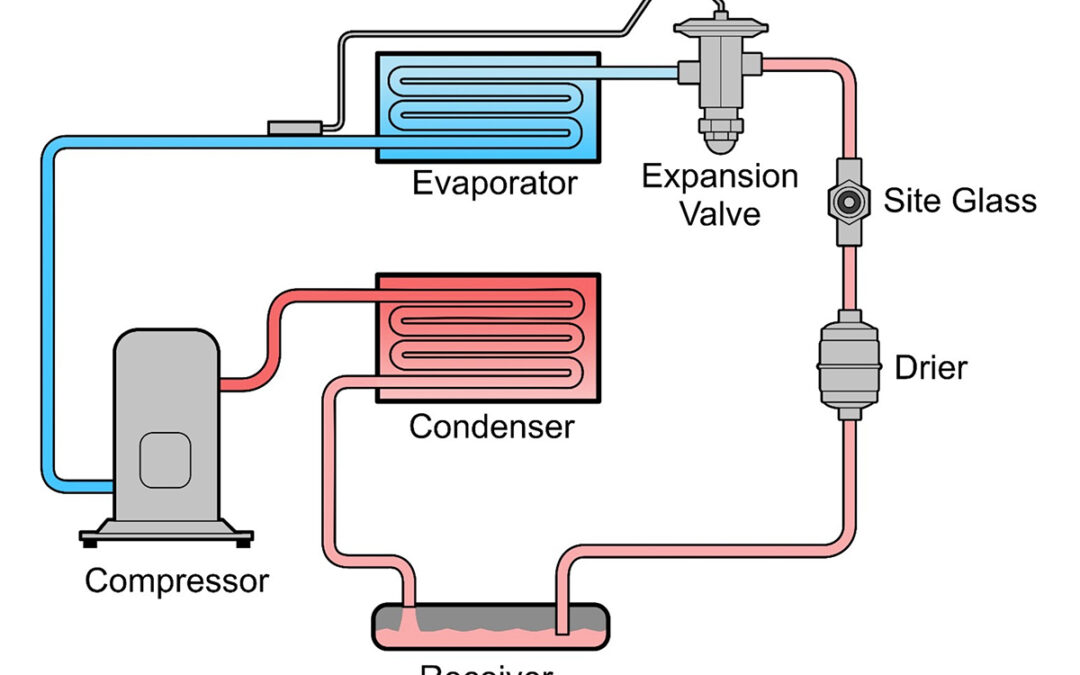

A cleanroom split system DX HVAC (Direct Expansion Heating, Ventilation, and Air Conditioning) is a type of cooling system commonly used in smaller cleanroom environments where central chilled-water systems may not be feasible. The system utilizes refrigerant to provide cooling and humidity control within the cleanroom and is designed to provide precise environmental control for cleanrooms, ensuring temperature, humidity, and air quality are maintained within specific parameters.