news & insights

How Does a Cleanroom Chilled-Water HVAC System Work?

A cleanroom chilled-water HVAC (Heating, Ventilation, and Air Conditioning) system is a type of cooling system commonly used in cleanroom environments to maintain desired temperature, humidity, and air quality conditions while providing precise and reliable control. The system operates using a network of chilled-water pipes and air handling units (AHUs) to deliver conditioned air to the cleanroom space. The system uses the mechanism of chilled water for cooling and heating purposes.

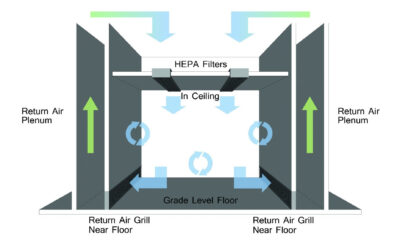

How Does a Cleanroom Air Plenum Work?

A cleanroom air plenum is an essential component of a cleanroom ventilation system. Located above the cleanroom ceiling, the air plenum serves as a reservoir for filtered air, and distributes filtered, conditioned air evenly throughout the cleanroom space.

How Often Should I Certify My Cleanroom to ISO Standards?

The frequency of cleanroom certification to ISO standards depends on several factors, including the industry regulations, the specific ISO standard being followed, the classification of the cleanroom, and the activities carried out within the cleanroom.

How Are Cleanrooms Typically Cleaned?

Cleanrooms require stringent cleaning procedures to maintain their sterile environment and prevent contamination in these sensitive areas. The cleaning process typically follows strict guidelines and protocols to minimize contamination and ensure the cleanroom meets industry standards. Some key steps in cleaning cleanrooms include:

What are Cleanroom User Protocols

Cleanroom User Protocols Cleanroom user protocols are a set of procedures and guidelines to ensure a controlled environment maintains a low level of environmental pollutants like dust, particles, and chemical vapors. These strict protocols and procedures are followed...

What is the Process for Decontaminating a Cleanroom?

Cleanroom decontamination is a process that involves the removal of contaminants such as particulates, bacteria, and other impurities from a controlled environment where high levels of cleanliness and sterility are required. A cleanroom decontamination schedule should always be considered during the design phase of a new cleanroom project.

New Hire – Jeff Meek

Precision Environments, Inc. is pleased to announce that Jeff Meek has joined our Team as Regional Sales Manager. He will be working from our corporate headquarters in Blue Ash, OH.

Cleanroom Flooring Systems

What Is the Difference Between Vinyl and Epoxy Cleanroom Flooring Systems?

What are Aerospace Cleanrooms?

Aerospace cleanrooms play a critical role in maintaining the quality, reliability, and performance of aerospace systems by providing controlled and sterile environments for manufacturing, assembly, and testing processes in the production of satellites, spacecraft, aircraft components, and sensitive electronics.

Five Cleanroom Technologies to Consider on Your Next Project

Cleanroom technologies are keeping pace with the continuous evolution of the cleanroom industry, here are five emerging cleanroom technologies that have gained attention recently: