news & resources

News & Insights

Visit the Precision Environments News & Insights page to read the latest company news, project highlights, and insights.

Knowledge Base

Visit the Precision Environments Knowledge Base to get information about Controlled Environments and the many technologies we deliver.

Marketing Resources

Visit our Marketing Resources library to access our product/service brochures.

Branding Resources

Visit the Precision Environments Branding Resources library to download our logos and brand assets.

Precision Environments News

A Guide to Cleanroom Wall Systems

Designing and building an efficient and hygienic cleanroom environment requires careful consideration of the wall system you use. Cleanroom wall panels provide the framework for your controlled environment, ensuring it meets strict standards of cleanliness and functionality. There are a range of wall panel systems tailored to different cleanroom requirements. Let’s explore the options available and the advantages they offer.

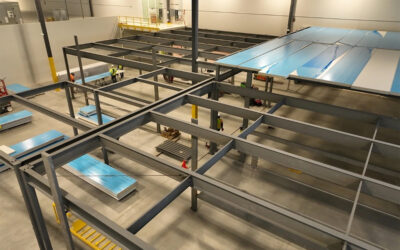

Structural Support In Cleanroom Systems

Cleanrooms are critical environments used in various industries such as pharmaceuticals, biotechnology, electronics manufacturing, and aerospace. Maintaining the highest levels of cleanliness and controlling environmental factors like particulate matter, temperature, humidity, and pressure is essential for the success of operations within cleanrooms. However, achieving these stringent requirements relies on the structural support systems that uphold the integrity of the cleanroom environment. In this blog post, we will look at some ways cleanroom systems are structurally supported.

Different Types of Cleanrooms in Various Industries

Cleanrooms serve as critical environments across diverse industries, ensuring product quality, safety, and compliance with regulatory standards. Let us explore several types of cleanrooms and give a quick look at their applications:

A Reference Point for Cleanroom Classifications

When it comes to creating a cleanroom environment, one of the fundamental questions that arises is, which ISO 14644-1 standard should be adopted?. These standards, ranging from ISO 1 to ISO 9, dictate the maximum allowable particles per cubic meter, with particle sizes ranging from 0.1 µm to ≥5 µm. However, understanding these classifications requires more than just numbers and ranges; it demands a real-world perspective on particle sizes and contamination sources.

An Introduction to the Question: What is a Cleanroom?

The cleanroom industry is diverse and intriguing, with each cleanroom tailored to its specific purpose. Unlike a one-size-fits-all approach, cleanrooms are uniquely designed to…

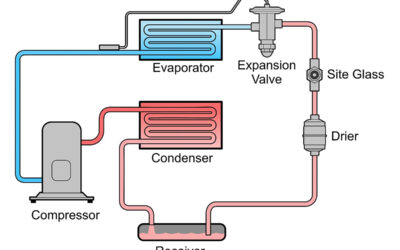

How Does a Cleanroom Split System DX HVAC System Work?

A cleanroom split system DX HVAC (Direct Expansion Heating, Ventilation, and Air Conditioning) is a type of cooling system commonly used in smaller cleanroom environments where central chilled-water systems may not be feasible. The system utilizes refrigerant to provide cooling and humidity control within the cleanroom and is designed to provide precise environmental control for cleanrooms, ensuring temperature, humidity, and air quality are maintained within specific parameters.

How Does a Cleanroom Chilled-Water HVAC System Work?

A cleanroom chilled-water HVAC (Heating, Ventilation, and Air Conditioning) system is a type of cooling system commonly used in cleanroom environments to maintain desired temperature, humidity, and air quality conditions while providing precise and reliable control. The system operates using a network of chilled-water pipes and air handling units (AHUs) to deliver conditioned air to the cleanroom space. The system uses the mechanism of chilled water for cooling and heating purposes.

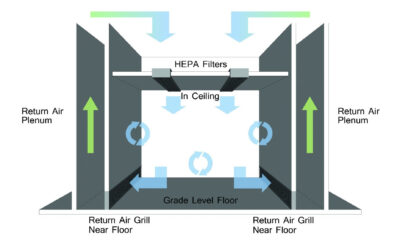

How Does a Cleanroom Air Plenum Work?

A cleanroom air plenum is an essential component of a cleanroom ventilation system. Located above the cleanroom ceiling, the air plenum serves as a reservoir for filtered air, and distributes filtered, conditioned air evenly throughout the cleanroom space.

How Often Should I Certify My Cleanroom to ISO Standards?

The frequency of cleanroom certification to ISO standards depends on several factors, including the industry regulations, the specific ISO standard being followed, the classification of the cleanroom, and the activities carried out within the cleanroom.